Research Areas

Nature Derived Materials

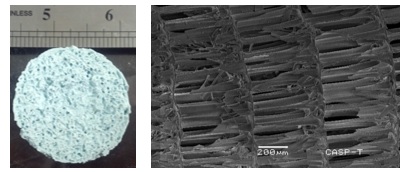

Keeping sustainability and affordability in view, BRR research group explores Pakistan’s rich biodiversity. Extraction of bioactive ceramics from fish-scales, use of biological templates and conversion of marine skeletons into scaffolds for guided bone regeneration are some of the key projects being undertaken by the group.

Porous calcium phosphate scaffolds for guided bone regeneration obtained via [a] naturally occurring organic templates (photograph) and [b] marine life skeletal sources (SEM image)

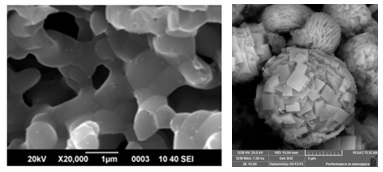

[a] The process of sintering due to heating of nano sized bioceramics as observed under a SEM [b] An SEM image showcasing unique tailorable morphologies of zinc phosphates obtained using microwave irradiation of suspensions

Novel Routes to Bioceramics

In addition to traditional co-precipitation routes to bioceramic synthesis, the group utilizes advanced synthetic routes such as batch and flow hydrothermal methods. A versatile synthetic route facilitates tailorable biological properties – hence making the desired structure-property relationship attainable. These approaches also facilitate high-throughput synthesis – hence facilitating nanomaterials discovery. Research also focuses on consolidation of these ceramics and utilization of Nanoceramics

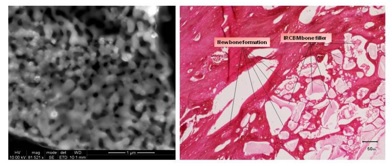

In-vitro & In-vivo Biological Evaluation

Dissolution and simulated body fluid studies are used to determine bioactivity of developed materials. Cell toxicity, proliferation and growth are used for in-depth evaluation of biological potential of materials developed at IRCBM. Animal models are employed for direct evaluation of bone regenerative potential of the developed bioceramics. Key collaborative ventures with leading veterinary and clinical concerns in the country facilitate these studies.

[a] An SEM image showing a porous calcium phosphate granules [b] Histological section as observed under a microscope after staining showing neo bone formation using IRCBMs bone fillers in the animal model

Bone fillers with different physical properties developed in large quantities at IRCBM

Scale-up & Commercialization

IRCBM scales up all technologies that are technically and financially feasible. Efforts have increased gram level yields of bone fillers to kilogram levels made using IRCBMs clean synthesis facility. Efforts are currently underway for filing of intellectual property rights, attraction of seed-capital, obtaining ethical and regulatory approvals for human trials etc.